Modeling & Simulations

Defense Systems

Simulations has been involved with a series of U.S. DoD programs since 2003.

As a design, analysis, and materials development firm, our specialty is conceptualization, prototyping, and out-of-the-box innovation.

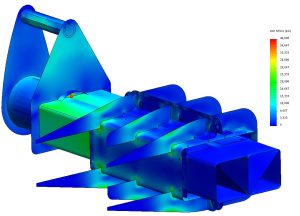

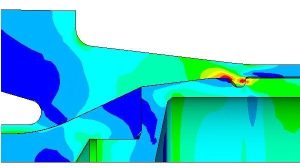

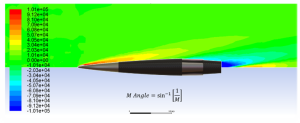

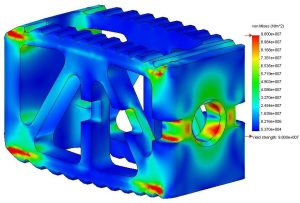

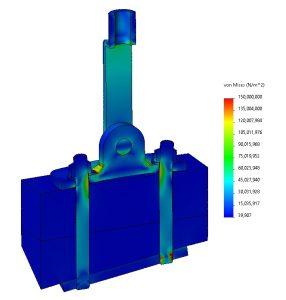

We perform non-linear implicit and explicit simulations daily using finite element analysis, computational fluid dynamics, 3D parametric automated modeling.

Our core expertise is from our decades of simulating and modeling:

- Propulsion systems

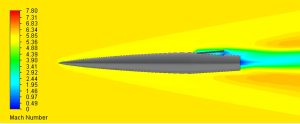

- Hypersonic projectiles

- Interior ballistic response of integrated gun-launched guide projectiles

- Rocket and missile structures

- Electromagnetic railguns and components

- In-flight aerodynamics and trajectories

- Lightweight composite sabots

- Aeroshell structures

- Marine transport systems

- Medical devices

Our team and technologists have engineered, designed, and fabricated military defense components for:

- The DoD

- Army

- Navy

- Office of Naval Research

- Strategic Capabilities Office

- Medical devices

- Military rotary and fixed-wing aircraft

- Automotive components

- Commercial off-the-shelf products

- Customized diagnostics

- Specialized tooling and molds

- Composite materials.

Manufacturing tool design capabilities:

- ANSYS LS-DYNA©. Explicit, time domain, fracture, incompressible and compressible fluids, impact, severe loading

- ANSYS Mechanical©. Implicit Solutions

- ANSYS Fluent©. CFD, Aerodynamic, Aerothermal

- CARES©. Ceramic Statistical Fracture Mechanics

- NASGROW®. Statistical Fracture Mechanics

- FRANC3D©. 3D Crack growth, fracture mechanics

- AwSIM©. 3D Composite Stiffness and Strength Prediction Tool (In-house developed code)

- FATE©. FEA Pre- and Post- Processor code for In-Bore Ballistic Structural simulation (In-house developed code)

- REAL©. 3D Pre-Processor Composite Layup and Fiber Alignment code aligning element coordinate systems

- SolidWorks Simulations©. FEA, Linear and nonlinear

- PRODAS™. Aeroballistic Design and Trajectory Modeling

- Mach 6+ Computational Fluid Dynamics Modeling

- Micro and Meso Composites Characterization using Representative Volume Elements (RVE)

- Ceramics Statistical Characterization Modeling

- SolidWorks© Suite of 3D Modeling and Design Tools

- SolidWorks© CAM/CAMWorks©. Computer Aided Manufacturing (CAM)

- ANSI, ISO, ASTM, MIL, NASA, DOD, FDA, etc.

Let’s Get In Touch

Feel free to leave us a message with inquiries, questions or comments.