Composites Engineering & Manufacturing

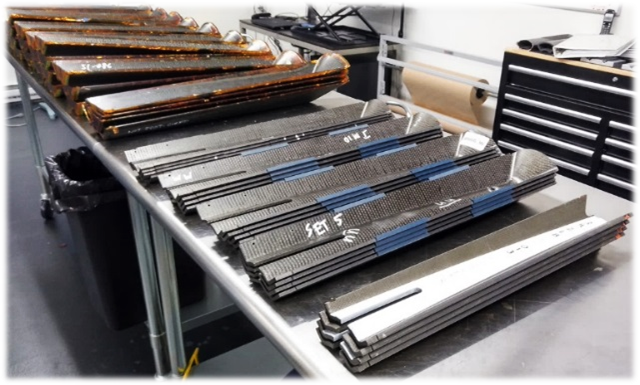

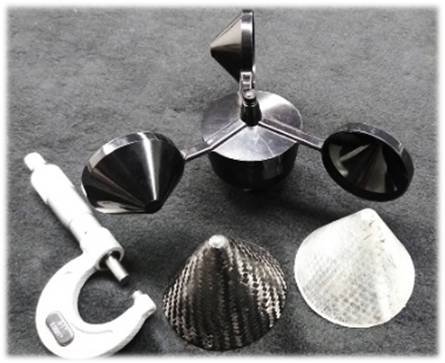

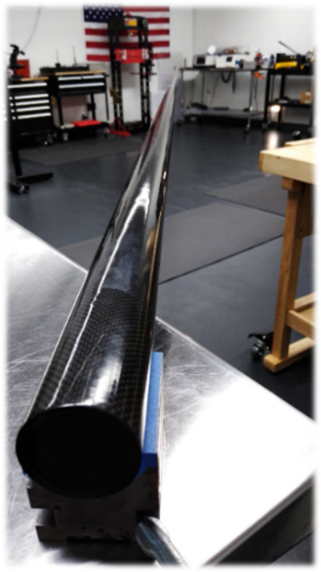

We are leaders in engineering and fabricating high strength composite components using boron and sister constituents.

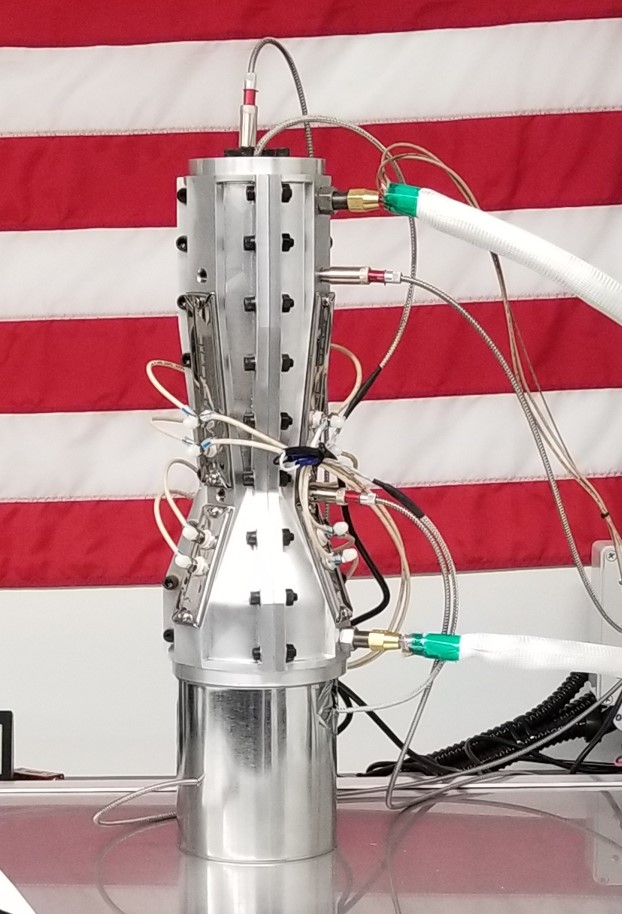

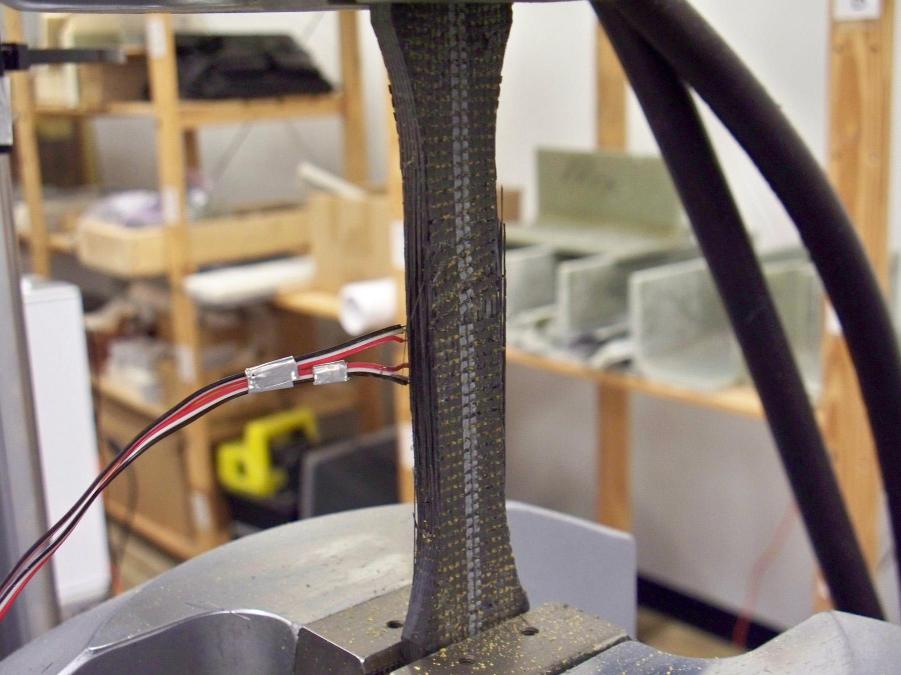

Simulations custom designs and manufactures composite materials. We perform structural, thermal, dynamic, impact, and fatigue finite element analyses. We developed our own in-house custom software tool AwSIM™ which predicts anisotropic strength and stiffness properties of the lamina, laminate and final components we create.

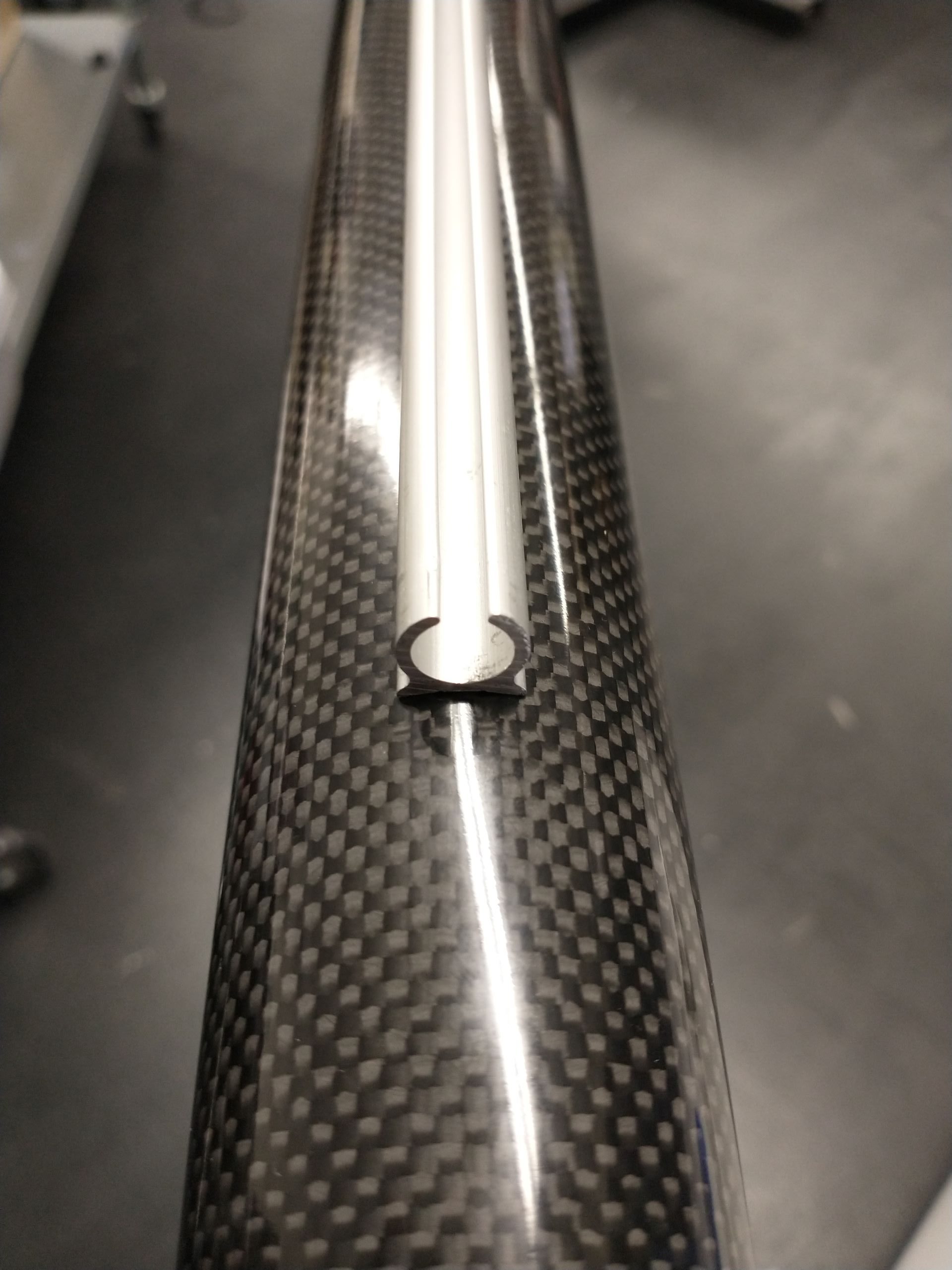

Boron-based composite design, manufacturing, machining and testing are a specialty and expertise of Simulations: all performed in-house.

AwSIM™ is our in-house developed software tool, based on classical composite theory that predict stiffness and strength. AwSIM™ utilizes the fundamental fiber and matrix constituent properties that characterizes lamina properties, which ultimately then allows AwSIM™ to predict the final part part stiffness and strength.

- Carbon, Boron, Glass, Nano fibers

- BMI, Cyanate Ester, Polyimides, Epoxies

- Walk-in and Bench Top Ovens, Dual Chamber Oven

- 2D Laminate and 3D Composite Design and Fabrication

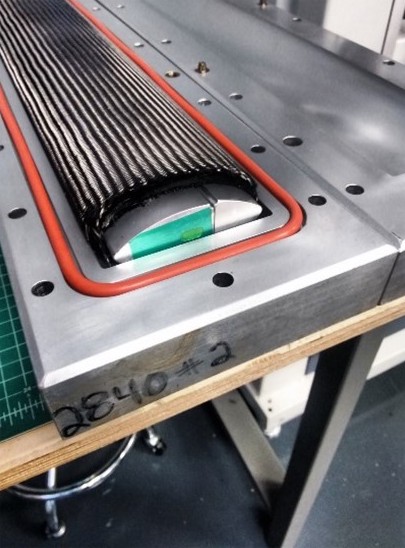

- High Pressure / High Temperature Resin Transfer Molding (RTM)

- Vacuum Assisted Resin Transfer Molding (VARTM)

- Compression Molding

- Complex mold design and fabrication

- Bladder, Dissolvable, & Expandable Trapped Rubber Mandrels

Let’s Get In Touch

Feel free to leave us a message for any inquiries, questions or comments.