Providing materials development solutions and hardware

for the defense and commercial industries.

Simulations is an end-to-end materials research, development, and fabrication firm.

Technologies and Services:

- Composites and materials development

- Mechanical, structural, and physics-based simulations and modeling

- Hypersonics and ballistics

- Lightweight structures

- Aerodynamic design

- Defense components

- Prototyping and production

- Marine transportation systems

- Medical devices

- Commercial product design

Featured Services

Our mainstay began as a modeling and simulations finite element analysis firm which continues to be the backbone of all our product development efforts.

Our technologists excel in:

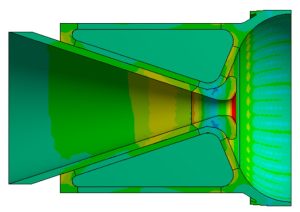

- Structural, thermal, aerodynamics, computational fluid dynamic (CFD) analyses

- Software development, custom coding within CAE, CAM, CAD

- Python, C++, Perl, MathCAD, ANSYS APDL

- Ballistics and propulsion engineering

We design, analyze, and build.

Our strong suit is versatility. We excel at specials. We like being different and prefer out-of-the-box projects. We perform the details.

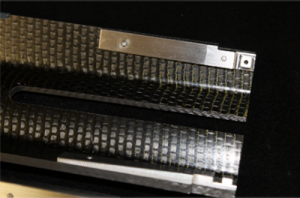

Simulations excels in structural analysis, composite material design, prototype fabrication and testing, in-bore and in-flight ballistic and hypersonic aerodynamic design, manufacturing, and testing. Simulations consists of a fully tooled CNC and conventional machining department, composites/materials development lab, state-of-the-art HPC servers, and engineering software. A brief list of our in-house and first-tier associates consists of material scientists, specialty prototyping and production fabrication firms, experts in structures, aerodynamics, composites tooling, weapons testing, computational fluid dynamics, electromagnetic propulsion, finite element analysis, and hypersonics. We design, engineer, and manufacture structures, components, mechanical devices and assemblies, hypersonic integrated launch packages, and conventional and novel high-energy defense propulsion components, as well as innovative commercial products.

Just some of our core capabilities…

- Analytical Engineering, Design, and Fabrication

- Composites and Lightweight Material Development and Application

- Finite Element Analysis, Computational Fluid Dynamics, Custom Coding

- Hypersonic Launch Package Design, Manufacturing, and Testing

- Carbon/Carbon Fabrication

- High Compression Strength Boron-Based Composites

- High Pressure Resin Transfer Molding (RTM) Design

- Bladder, Expandable Mandrel, Vacuum Assisted Resin Transfer Molding (VARTM)

- Composites, Metal, and Exotic CNC and Conventional Machining

- Non-Destructive ASTM and Custom Materials Testing

Come See Us